Official Page Launch February 2nd 2018!!!

© 2018-2019 Desert Fabworks LLC - CNC Plasma Info, All Rights Reserved- Trademarks shown on this site belong to their respective owners

Grounding? That’s what I thought when I started this build. Everything is grounded via the electrical system right? - Green Wire in the plug? My first Plasma Table only used the electrical grounding that it received from the electrical system, it worked fine and I had no problems so I never realized I would need more.

The experts that I consulted said that yes sometimes you can get away with not having extra grounding and you are just lucky. As the systems get larger and higher power grounding becomes a necessity not just an option.

When grounding these tables you are not necessarily grounding to prevent shocks your doing it more for the “Noise” and EMF - Electro Magnetic Fields and pulses that are created from the plasma cutting machine and the information and power being sent through the various wires.

There are three basic types of noise: (1) High Frequency from HF Starts machines. The Hypertherm Powermax65 does not use HF Start and is not a problem in this case but older and larger industrial units do use this. (2) Noise generated from the plasma power unit that it feeds back into the electrical system even if its on its own circuit. (3) Noise from the Arc its self.

I talked with Jim Colt of Hypertherm and got some great advice for dealing with these problems, here is what he recommended:

A good power line conditioner, or a UPS with power line conditioning is a good recommendation for 120 volt power for the electronics and the computer.

Cable routing is critical....if cables are too long coiling them makes it easier for the cables to pick up noise inductively from other cables.

If a 5v logic level computer signal is next to a plasma cable that could have transient voltages of a few hundred volts....the the signal on the computer cable will cause issues. Shorten and separate any and all cables....they can run parallel with each other, but should not be coiled together.

The Plasma power supply operates at high (over 700 volts) and at switching frequencies that make these voltages couple inductively very easily. It is also a magnet device....using some fairly big inductors and transformers that create a magnetic field. By putting this power supply inside the same steel frame that the computer and electronics are in...is essentially like building a steel transformer....the likelihood of electrical noise issues is increased.

Normally...on all cnc machines a ground rod is driven 6 to 8 feet into the ground, right next to the machine. The work ground for the plasma attaches to this rod, as does a heavy gauge cable from the plasma gantry and torch carriage of the machine...as well as the computer chassis and the electronics chassis. A cable the same size as the work ground also goes from the ground rod to the table slats. The plasma power supply and the cables are normally run and placed away from other cables....some manufacturers even use dual powertracks...one for plasma cables, one for motor, drive and electronics cables.

Many people may consider this an optional step, while some may get away with it on lower power machines it can cause the little gremlins in a system that are impossible to track down because they are hard to replicate. This is a best practice recommendation and as higher power plasma units come into play it becomes more important.

All of the items need to complete this step can be purchased from most home improvement stores or Amazon.

Don't skimp on the ground rod put the full 8 feet of the 5/8 into the ground. Use or rent one of the SDS drivers that goes on the end of a hammer drill to make the process much easier.

More Photos and info to come

So here is what I did: First thing I did was place a UPS power supply in the system. All of my components running off 120 volt will plug into this ie: computer and cut controller box. This will do two things. It will provide clean filtered electricity to those components and keep noise that may be in the electrical lines from the plasma unit or just noise from the electrical system in general out. It will also keep my system up and running for about 10 minutes should there be a power failure giving me time to save things and note placement on the table.

The second thing I did was drive an 8 foot 5/8 copper grounding rod into the ground right next to the table. Keeping distances short is very important. Sometimes this is not easy. Lucky for me the machine is up against an exterior wall so the rod was put just outside keeping the cable run short. I used individual ground wires for each ground lead. I used an SDS driver bit for our rotary hammer to drive the rod. 8 feet is a long ways and the bit was expensive but worth it.

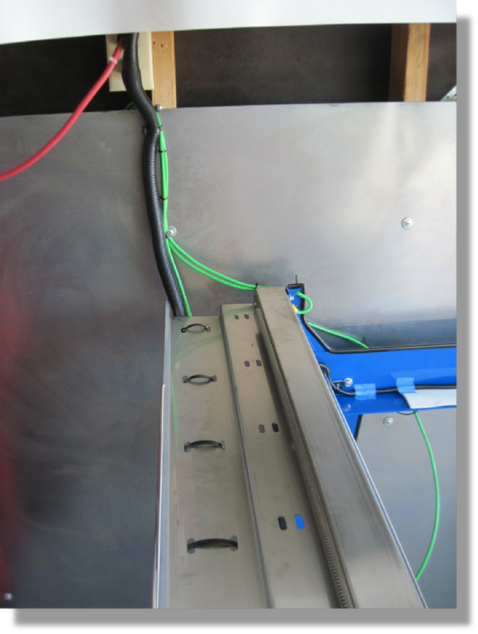

The EMF and noise tends to travel on the outside of wires. To ensure that we capture this noise and transmit it as effectively as possible to ground I used 4 gauge Stranded cable. The noise like electricity takes the path of least resistance. Having large gauge stranded cable lowers the resistance.

The other thing that is important with grounding cable is “homing” the cable. This means running an individual cable for each item you are grounding. Don't take the easy route and daisy chain the components. Run and individual wire for each item.

I ran a ground wire for the Pan (same location as ground lead from plasma machine) The table gantry, the computer, and the plasma machine its self. This gave me 4 individual ground leads all “homed” back to the ground rod.

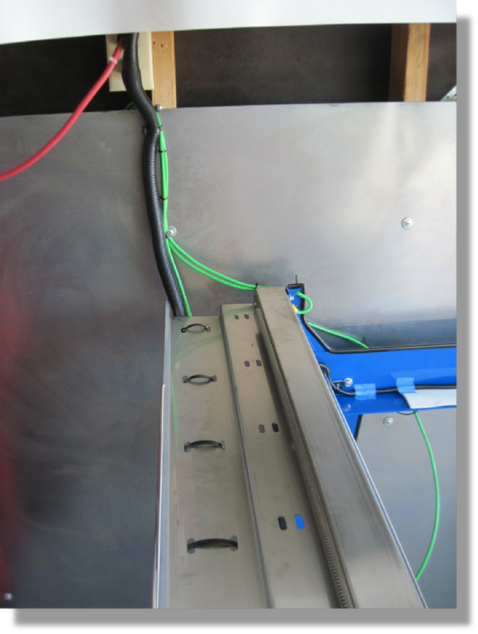

My last couple lines of defense are proper cable routing. I made sure to route the cables so I could minimize coils, keep all cables as short as possible and avoid cables crossing each other. I kept the cable runs parallel as possible. Since the cable trays are on the gantry and are grounded that will help pull any noise away from the system. The last line of defense are Ferrite Core RFI / EMI Chokes. These are the same devices that you see molded into a lot of your common computer cables. They are inexpensive and plentiful on Ebay and Amazon. I got a bunch of these to clip onto our cables running from the motor control unit and computer.

Hopefully I will have no problems with all of these measures in place. Keeping your plasma unit as far as possible from your other components is a good idea as well.